This post is a log that I kept during the interior remodel project on our ’76 GMC. For a long time – then, August 1st, 2010 until now (March 2013) I had “lost” the log, could not find it anywhere. Today, I found it and decided to make it into a blog entry – even I am interested in how I remodeled the interior of our coach in only 8 weeks.

The photos included with this log show the original look, some of the work (I was too busy to take many photos) in progress on that particular day, and then the final results and some things that have happened since.

First, a couple of photos that the previous owner (Uncle Dave) took of the interior:

Next, some photos that I took when I realized that I was well into the job but had not taken a single photo of the interior before I started or even during the first week. These photos were taken on June 9th – at least a week into the project:

A couple of days later I took some more photos. These were taken on June 11th:

The following text was written as a log during the project. Photos are placed in sequence of when they were taken.

Lots of activities before this but cant’ remember everything and when so will start from here – June 16th – I did well remembering most of yesterday but not before in any detail. Will try to do better.

June 15th, 2010

I planed down the wood strips for the ceiling and bent them to match ceiling curve. Temporarily installed them on the ceiling to dry and hold the shape.

Tried out seat prototype but now need the second seat to see how they go together.

June 16, 2010

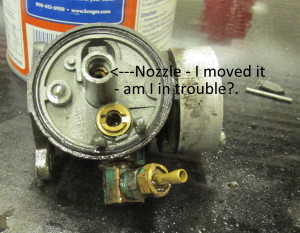

Today I inspected the wood strips that will hold the ceiling joints up – they have dried and are pretty color-free. I got underneath the back and put the washout nozzle into the hole that the OEM-style level sender was in – I had drilled the washout flange to match the holes in the sender. I took another look at the macerator discharge hose and I think that the kink is not bad enough to cause a problem – I will test before we go.

I installed the AC Delco 15-4644 fan clutch and removed the Haden 2927. It sounds like it is running closer to engine speed but we’ll see. The engine battery is dead again even tho it was disconnected since it was parked there upon return from Calif.

I made up the second seat pedestal prototype – the one that is wider and goes up front. Tomorrow we will put it in and make final decisions on the size and placement of the pedestals, table and bench/cabinet.

I cut down the Create-a-Breeze bezel to match the depth required and some 1/2″ spacers to hold the ceiling out at the right level.

Made the trim piece that goes on top of the closet unit and holds the ceiling up.

Ordered some stainless steel sheet metal screws and recessed washers from McMaster-Carr.

June 17th

This morning – 7:00am – we (Carol too!) arrived at the storage lot and put screws into the ceiling panels that needed them (sagging FRP) and put some trim up over the closet. Put the trim for the Create-a-Breeze and took down the maple strips since they are now dry from the bending.

Cleaned up a lot of the screws and trash that has been accumulating.

Put prototype of second dinette seat in place and measured for table and overall placement of the dinette pieces.

Took the maple strips home and Carol sanded and applied 3 coats of poly while I cut and edge-banded the doors and drawer-fronts for the closet unit. Then I applied the veneer to the bathroom door.

The macerator pump arrived today – can now finish the holding tank repairs and upgrades (replace macerator, try to fix the sending sensors, install washout).

June 18th

Finished putting veneer on the closet and bathroom doors – Carol is applying poly – they look good.

Now to start on the kitchen and the dinette. First step is a design.

Stove arrived today and we went out and found a single bowl stainless sink at HD that will fit in the allotted space.

Carol is still working on polyurethane coatings of everything – having a hard time because of heat?

My back is killing me so not much today.

June 19th

Up early – off to install macerator and cleanout hose then will be done with black tank stuff – I hope.

Got that done and now it is time to start putting the new doors and drawer fronts together so we can get those installed tomorrow morning

Started cutting pieces for face frame of kitchen. Laid out the stove and sink and thought up a way of extending the counter top with a swing-up extension.

Have not finished ceiling yet but have to make one more trim piece to go over bath to hold ceiling panel up – hope to get the ceiling finished early in the week and move on the replacing the fan shroud to get ready for a test run to see if we need a radiator. Also, have to remove antenna and get some polyurethane adhesive caulk for around the FFF (our term for the Create-a-Breeze). Also have to get a replacement engine battery.

Back getting better but still a problem. Rest after a little bit of work tomorrow morning.

June 20th (Fathers’ Day)

got down there at about 8:00am and put the doors and drawer fronts back up – looks great but forgot, for now, to take photos. Took about 2 hours.

That is it for today – breakfast, movie (Schreck??), the US Open and sleep in order.

June 21st

Schedule for today: see how to get the doors off the refrigerator so I can cover them in maple, attach the maple strips to the ceiling, make a trim piece for over the bathroom door, work on the face frame and the partitions between cabinet sections.

Can’t get doors off without a special wrench. Maple strips now screwed to ceiling except for bath/closet area where I need a trim piece first. Work on face frame and cabinet starting today.

June 22nd

working on the kitchen cabinet – tried it for fit today and it is ok so will proceed with building out the various spaces.

Made and installed the trim over the bath door to hold the ceiling up.

Going out to buy more supplies – lumber, shower curtain hooks, vent covers, paint, etc.

Went down to the storage lot at 7:15 since it had cooled off but it got dark by 8:00. I removed the 3 old plumbing vent covers and did first pass cleanup of the area around them. The refrigerator vent is pretty rusty and it looks like it is not sealed real well so started taking it off but several screws will not budge so drill and easy-out tomorrow. Also, the antenna needs to come off and be sealed all around it – tomorrow too?

Carol thinks the passenger side buffing is done except for a small strip at the top. Much easier to do in the evening.

June 23rd

Started morning by removing refrigerator vent and old antenna. The vent is in pretty bad shape so will look for another.

Worked on the kitchen cabinet – getting close. Bought a refrigerator vent but don’t know if I like it. Will call Jim K tomorrow to see what he has.

June 24th

Changed my mind about waiting for another vent – rain started showing up in the forecast and it (the vent) looks OK. Installed 3 plumbing vents, patched (with aluminum flashing) the 2″ hole left from the antenna, sealed around the Create-a-Breeze, and installed the refrigerator vent. Put a couple more screws in the most forward ceiling panel and switched from buttons to washers in that panel to see what we like best.

Took the coach down from the rear ramps and put them under the front to prepare for the shroud replacement.

Got the refrigerator doors off so we can now cover them in the maple veneer.

Carol got the table edges refinished – sanded, stained and a couple of coats of poly. We will use it for now.

Worked on the kitchen cabinet – made the slide out that will hold the counter extension and fit around the sink.

June 25

Hope to get the old fan shroud off today. Maybe start working on the new one?

Got it off along with two of the 4 brackets. One of the remaining brackets is on the same bolt as the A/C compressor and the other, also on the passenger side is involved with the axle. Had a bit of a time getting the new one on – still have to go and buy some bolts and other stuff to finish. Also, had to remove (again) the fan and clutch – ugh.

Will work on the refrig panels and the drawers for the kitchen.

OK, got the refrig panels veneered and installed the drawer slides. Dr. appointment today – will stop at Ace to get bolts to complete shroud install – so that’s all for now.

June 26

Got the bolts so will put it all back together this morning. Will probably work on drawers for kitchen but my back hurts and we are hosting a taco party tonight so will quit early. Anniversary tomorrow – 23 years.

Got the shroud in and took it for a ride – still runs hot according to the temp gauge but I am curious about why the fan clutch – now the AC Delco 15-4644 – does not come on until the gauge reads 235 to 240. Carl Stouffer thinks that maybe the radiator is plugged so that no water is passing through it and it doesn’t get the fan clutch hot enough to turn on. Steve Ferguson thinks that the temp gauge is wrong and that the radiator is probably working OK since we should be hearing stuff – like pinging – if we are really running that hot. He suggests getting a good mechanical temp gauge like an Autometer, or Stewart-Warner. Next week.

June 27

Installed the newly covered refrigerator panels this morning and they look great. Will get some photos asap.

Tomorrow: work on the kitchen cabinet – drawers and then give it to Carol to sand and varnish. Get some cardboard to make template for side to sidewall curve. Buy mechanical temp gauge.

June 28

Made the drawers for the kitchen. Cut and machined the pieces for the face frames on the upper cabinets. Bought a mechanical temp gauge and verified it in a pan of boiling water – found a web site that tells you the boiling point at the atmospheric pressure and altitude where you are – was exactly correct. Will try to install it tomorrow.

June 29

Installed the temp gauge and took it for a ride – the temp is a little high. Got to 225 climbing the hill with air temp of 95 degrees. The fan came on at about 220 and stayed on as long as I was going slow. The temp did drop when the fan was on as opposed to the way it seemed with the old temp gauge. I think the radiator has a problem – will talk to Steve Ferguson and Tom at AZ Mobile Mech. to see what my options are. Also will check on why the Tracker’s rear tires are wearing so badly.

Assembled the face frames for the upper cabinets. Tomorrow will trim them and start cutting plywood for bottoms, backs and ends.

Tomorrow morning I plan to finish the ceiling completely. That means installing another trim piece over the closet, installing the battens on the seams in the aisle, re-attaching the Create-a-Breeze trim piece. Carol will wash the walls to be painted and we will mask the windows and other stuff so we can paint the walls.

June 30

Finished – finally – the ceiling this morning. Started masking for painting the walls forward of the kitchen and door. Painted the FRP panels in the dinette and couch area with same paint as closet, bath, etc.

Trimmed face frames for upper cabinets and started figuring out how to make the bodies.

July 1

Will see how the interior painting went yesterday when I pull the masking off. Plan to install the kitchen cabinet today so I can measure for the couch and the counter top.

Got the kitchen cabinet installed, finished the painting started yesterday – missed some spots, and re-installed the dining table in the slightly adjusted location. More work on the upper cabinets if I can stand the heat – the humidity is getting higher lately.

Did some work on the upper cabinets – cut the plywood bottoms and backs for all of them and now to figure out how to join the backs to the bottoms at the 10 degree angle required.

July 2

Assembling upper cabinets. Made the ends and middle pieces from a template rescued from one of the old cabinets. Using biscuits and glue – maybe some screws with wood filler plugs at the back.

Got all the pieces cut for the 4 cabinets and got one of the small (bedroom) ones assembled – just need to put the mounting cleats on the top and back. More tomorrow.

July 3

Assembling more cabinets – almost done with major parts then will have to put inside false bottoms, shelves and mounting ribs on, round the bottom edges and give them to Carol for sanding and varnishing. Probably will get all that done on Monday???

July 5

Will begin work on kitchen back splashes – left and back – and getting profile for valances.

Got profile and sizes for back splashes and plan for implementation but no start. Got profile for valances and cut a bunch of poplar for returns. Made appointment with Tom at AZ Mobile to fix radiator issues and install timing tab. Sanded upper cabinets and Carol put first coat of poly on them.

Tomorrow – measure for kitchen doors and drawers in case I need more work to do while Tom has it. Rework wiring behind kitchen counter for outlet and microwave – bought shallow boxes so they won’t interfere with backspash’s fit against wall.

July 6

Got the wiring reworked and the kitchen stuff measured. Planed returns on valances and cut most of the vertical pieces – discovered that the vertical dimension will be different if there is a cabinet in front – if no cabinet the valance will be taller to cover the old holes. Took the GMC to Tom and it may or may not get back to us by Thursday afternoon – if not will start making doors after valances are done.

July 7

Made valances – two for large front windows – skipping door for now since I can’t measure (until I get the GMC back) and it is a complicated fit. They will be ready for Carol to sand and varnish tomorrow. Will leave the bedroom valances until our return later in the Fall.

July 8

Sand the valances and then give them to Carol to finish. Begin work on the couch. Got most of the couch body and face frame done – will finish trimming the edges of the plywood and then make the drawers when I get the materials for that. Will do as much as I can on the couch tomorrow and then start on the dinette pedestals.

July 9

Finished the couch body and prepared for Carol to varnish. Began dinette pedestals – keeping them simple.

July 10

Working on the dinette pedestals. Finished those except for some magnetic catches to hold the removable sides and some sanding and now started cutting wood to make doors and drawer fronts.

July 12

Cut out the back splash plywood and covered the side one with laminate – still needs to be trimmed. The back splash needs to be fitted to the coach before I cover it. I also covered the pantry door with veneer so it will look ok for this trip – will replace the whole refrigerator unit in phase II. Had to quit for the day because my back/hip is hurting too bad – time for another massage for $60 – ouch.

July 13

Finished side splash – ready to install. Now cutting rails and stiles for cabinet doors – Carol helping so I do not stress my back more than is necessary. Radiator arrived at Tom’s yesterday he is having some issues with having to move the steel pieces that hold the rubber cushions. Got all the rails and stiles cut and planed and got the inside edges shaped. All rails are cut to length so just need to shape the ends. Time to make the panels but need to get more wood – tomorrow.

July 14

Shaped all the ends of rails. Went to the lumber yard and got more maple for door panels, a sheet of baltic birch, drawer guides and a sheet of 1/4″ mdf for the drawers in couch and hinges for all of the cabinet doors. Tom will hopefully have coach radiator done tomorrow. I guess the first thing we ought to do is get a new engine battery.

July 15 – 17

Installed new engine battery when I got the coach back – amazing difference in starting. Made panels for doors and assembled and trimmed doors. Ready for sanding. Cut out backsplash and covered it with Formica and installed it. Cut out counter top got it ready for Formica.

July 19

Covered counter top with Formica. Installed the valances and shades on the two front windows. Removed the large valance on back window so we can try to trim it narrower. Went to the plumbing shop to get some parts to plumb the sink but no luck – I don’t know what size the pipes are in the GMC so I don’t want to cut them – will probably just put the ‘P’ trap under the sink like it used to be. Now to figure out how to make the door valance, trim the large valance in the back and hang the upper cabinets. Right…

July 20

Cut down the depth on the rear valance to try to improve interference with sleeping space. Put 1/2″ rounded front edge on kitchen countertop. Did edge work on all doors and drawer fronts. Reinstalled rear valance and installed new shade into it along with the two side shades in bedroom. Started figuring out how to mount upper cabinets. Called Sandy’s West and they have 1 1/4″ ABS pipe and fittings so I will be able to manufacture my own p-trap.

Plan for tomorrow is to begin or even finish mounting the upper cabinets. Go to lumber yard and get more maple for stuff that is left – countertop extension, wire channel covers. Go to Sandy’s West for plumbing parts needed to plumb kitchen sink. Get bolts and nuts needed to install couch, dinette and upper cabinets.

July 21

Still working on mounting the upper cabinets – designed and installed rear spacers so valances can fit behind them, have an idea how to do the top spacer and do the initial attachment to the ceiling. Carol is varnishing the doors and drawer fronts. I bought the plumbing items and the lumber and the bolts to get close to finishing the project.

Tomorrow – hang the upper cabinets (help needed for this) – plumbing, counter top, stove, sink.

July 22

I finally got the upper cabinets hung. It was not just a matter of duplicating the old mountings because I wanted the valances to go all the way around the window and there was not enough room for it (2″) in the old mounting. I made the rear mounting rib wider and that pushed the cabinet out. Pushing the cabinet out made the dimension of the upper mounting rib change so I had to remake one of them and I had to use a less than ideal profile on the other. I should have made a mock-up of the cabinet profile and used that to determine the dimensions – next time ;-)…

July 23

Installed plumbing – had to remove old stuff and put in my own version of a p-trap made from pipe and elbows and adapt it to 1 1/2″ tubing from sink. Installed counter top, sink and stove. Hooked stove to gas and connected water to faucet. Have to wait for glue (sink is glued down) to dry before I can connect the drain and try everything – tomorrow. Also tomorrow I plan to install the cabinet doors and drawer fronts and, hopefully, get started on prepping for the floor.

July 24

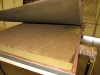

Installed doors and drawer fronts on kitchen and upper cabinets. Took the upper cabinet off and installed it again!! We decided that the microwave was going to stick out too far – about 4″ – and wouldn’t look good so we took it down and cut out the back to allow the microwave to slide in and unfortunately we only gained about 2″ more inward. Now there should be about 2″ overhang and I’ll make it look good – I hope. Got started prepping for the floor. Took the carpet off the steps and found a rotten spot that opens to the driver’s side wheel well – about 6 x 8. I am going to patch it but I am not going to worry too much since it will not show anyway – it will be under the foot of the couch. Removed lots of staples and cleaned it all up. Some rotten spots but not much to worry about so I will just leave them since they are not under traffic areas – in the kick area of the closet and the corners next to the first step. Put the first two courses of flooring together – looks great and we should be able to get it done easily by tomorrow. Also got the sink drain connected today – no leaks but I don’t know how well it will drain since not much slope due to the deep sink. Tomorrow is Sunday and I usually take the day off and we figure out something that we both want to do but no time so at least some work tomorrow.

July 25

Installed the floor everywhere except for the step which has to get fixed and under the bed which may or may not get installed. Back hurts too much to do more today. Tomorrow will install the couch and dinette and maybe install the pantry door. Bolting the couch and dinette down requires putting the coach up on the ramps at Ed’s and that is the time to change the oil too. Also have to salvage usable stuff from the old upper cabinets and tossing the remainder into Ed’s dumpster. That will clean out much of Plocher’s garage.

July 26

Had to spend time this morning installing some patio lighting for a former neighbor who is returning while we are gone and who has already paid me. Cut and installed the Pergo on the step to the flight deck. Cut the FRP and the foil insulation for the two risers. Went on a trip to get more paint for the FRP and to get the stair nose pieces, bolts to hold the couch and dinette down, and oil and a filter for the oil change that we must do before we leave. Tomorrow, finish the stairs and install the couch and dinette pedestals and maybe the pantry door.

July 27

Finished the steps today and installed the noses. Cleaned up the old cabinets and threw them out – Ed’s dumpster. Put the couch and pedestals in the coach and it looks good. Made the drawers and installed the slides in the openings before we put it in the coach. Also installed the pantry door – needs a catch. Tomorrow install the drawers and drawer fronts after the couch is bolted down – plan to change the oil during the bolt down process. Also, make a piece of plywood to set across the top of the couch drawers and serve as a place to put a pillow and be a foot rest. After all that is done make the wire cover molding and install the lights.

July 28

Tried putting drawers in under couch and broke one side of one of the drawer guides. Took the coach down to Ed’s and up on ramps for oil change, drain excess fluid from tranny and bolt chair pedestals and couch to floor. Needed longer bolts for chairs and then found needed even longer bolts for couch so not quite done yet. Working on installing microwave. Found that I can run one air conditioner using a heavy duty extension cord from a standard 20 amp circuit. Got the oil changed and drained some excess tranny fluid by removing vacuum modulator after running and then shutting down engine to make sure that the torque converter was full. Finally got the furniture bolted down and got the Honda seats attached to the pedestals. Repaired and painted the old door bottom panel – install tomorrow. Also had to cut the OEM table down again because the floor got 5/8″ higher.

Tomorrow: cut the foot rest plywood pieces for the couch drawers, make the wire cover moulding, install some lights, install the bottom door panel. Install shelves in 3 of the cabinets using stuff from old cabinets.

July 29

Installed lower panel and shade on entry door. Installed lights over bed, kitchen counter (over stove later), and couch. Got wiring ready for lights over dinette. Got trim piece made to cover wire conduit on passenger side and installed lights over dinette chairs. Also, put shelves into upper cabinets.

July 30

Tacked up baseboard under kitchen and under pantry. Hung up clock. Installed roller catches on both couch drawers. Found the new radiator leaking at the overflow outlet which had been stripped and cross threaded – put it back in with epoxy around it and, hopefully, in the threads. Made the counter top extension – will not install it until later, just put it into place when we want to use it. We are done and ready for the trip.

Share on Facebook

Share on Facebook